PVA adhesives

|

Description:

Properties: |

|

|

Description:

Properties: |

|

|

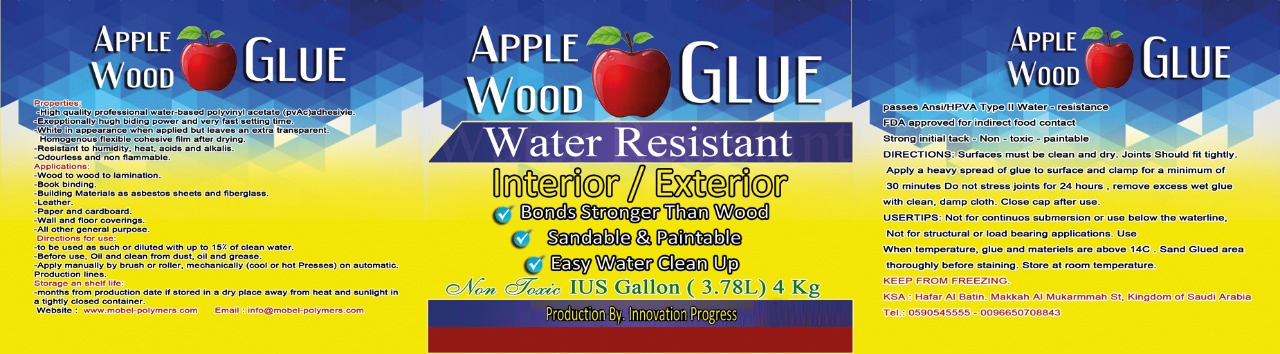

Properties:

Applications: |

|

Homopolymers

|

Description: |

Shelf life: |

||||||||||||||||||

|

Application fields: |

Properties:

|

||||||||||||||||||

|

Storage conditions: |

Packing: |

|

Description: |

Shelf life: |

||||||||||||||||||

|

Application fields: |

Properties:

|

||||||||||||||||||

|

Storage conditions: |

Packing: |

|

Description: |

Shelf life: |

|||||||||||||||

|

Application fields: |

Properties:

|

|||||||||||||||

|

Storage conditions: |

Packing: |

|

Description: |

Shelf life: |

||||||||||||||||||

|

Application fields: |

Properties:

|

||||||||||||||||||

|

Storage conditions: |

Packing: |

|

Description: |

Shelf life: |

||||||||||||||||||

|

Application fields: |

Properties:

|

||||||||||||||||||

|

Storage conditions: |

Packing: |

|

Description: |

Shelf life: |

||||||||||||||||||||

|

Application fields: |

Properties:

|

||||||||||||||||||||

|

Storage conditions: |

Packing: |

|

Description: |

Shelf life: |

||||||||||||||||||

|

Application fields: |

Properties:

|

||||||||||||||||||

|

Storage conditions: |

Packing: |

Copolymers

|

Description: |

Application Fields: |

||||||||||||

|

Packing: |

Properties:

|

|

Description: |

Properties:

|

|

Description: |

Application Fields: |

||||||||||||||||

|

Packing: |

Properties:

|

|

Description: |

Application Fields: |

||||||||||||||

|

Advantages: |

Properties:

|

||||||||||||||

|

Packing: |

|||||||||||||||

|

Description: |

Application Fields: |

||||||||||||||

|

Packing: |

Properties:

|

Plasticzers

|

Description: |

Properties: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specification:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical Properties:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Plasticizing Efficiency: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Compatibility with Limited in comparision of DOP. Secondary Plasticizers: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Packing & Storage: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Shelf Life: |

Safety: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Disclaimer: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Description: |

Properties: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specification:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical Properties:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Packing & Storage: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Shelf Life: |

Safety: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Disclaimer: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Description: |

Properties: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specification:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical Properties:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Packing & Storage: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Shelf Life: |

Safety: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Disclaimer: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Description: |

Properties: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Specification:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical Properties:

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Packing & Storage: |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Shelf Life: |

Safety: |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Disclaimer: |

|||||||||||||||||||||||||||||||||||||||||||||||||

Recycled lube oil

|

Specifications:

|

|

Specifications:

|

|

Specifications:

|

|

Specifications:

|

|

Description: |

|||||||||||||||||||||||||

|

Properties:

|

|||||||||||||||||||||||||

|

Applications: |

Features & Benefits: |

||||||||||||||||||||||||

|

Description: |

|

|

Features: |

Specifications: |

Thinner

|

Description: |

Application Fields: |

||||||||||||||||||||||

|

Shelf Life: |

Properties:

|

||||||||||||||||||||||

|

Storage Conditions: |

Packing: |